Developing a Lung on a Chip

Project Title: Microfluidic-Based System for Mimicking Human Organs

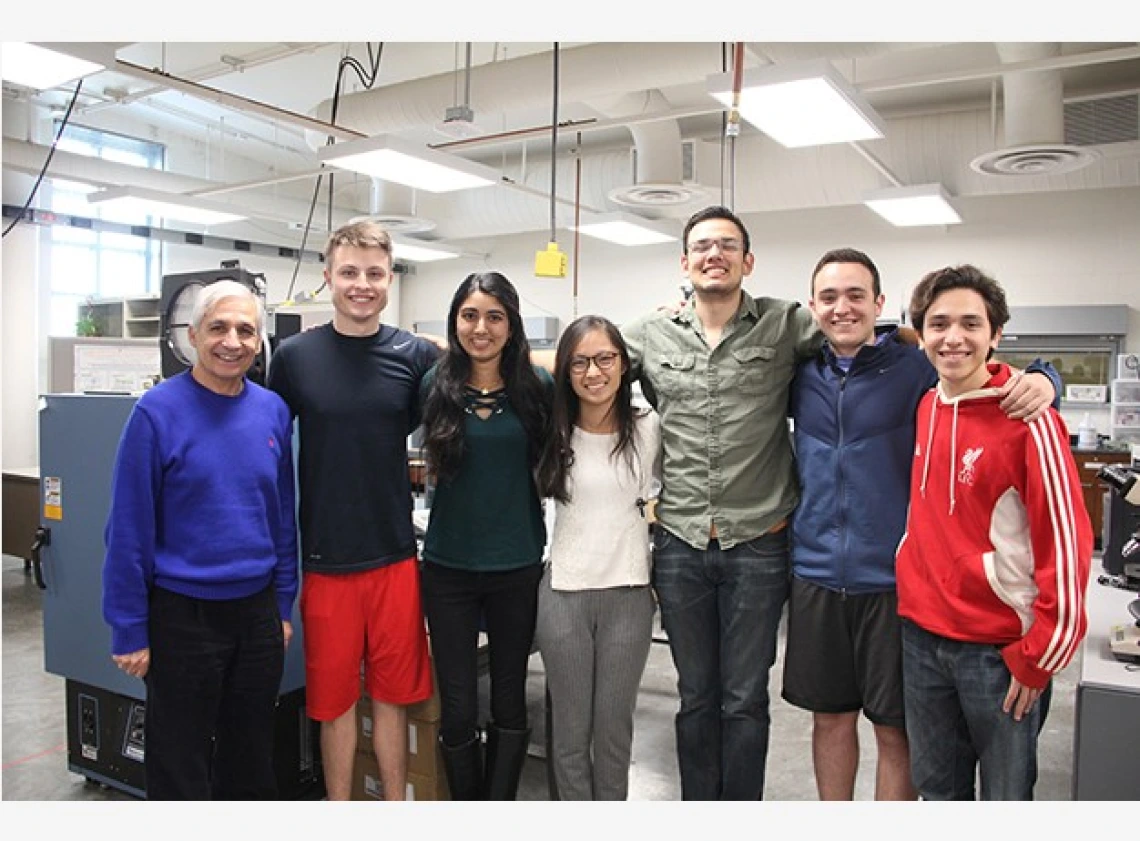

Team 17047 Members:

Fernando Albelo, biomedical engineering

Bailey Bellaire, biomedical engineering

Apoorva Bhaskara, biomedical engineering

Victor Estrada, mechanical engineering

Adolfo Herrera, mechanical engineering

Meagan Tran, biomedical engineering

Sponsor: UA Department of Biomedical Engineering

Organ-Imitating Device Could Mean the End of Animal Testing

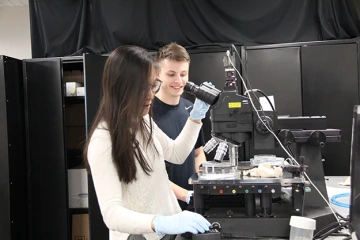

Undergraduate biomedical and mechanical engineers in the University of Arizona’s Engineering Design Program are teaming up to create a “lung on a chip,” a microfluidic device that could offer a new method for testing treatments and identifying how practices like smoking e-cigarettes affect the lungs. Microfluidics is the science of working with fluids on a submillimeter scale.

Using epithelial cells, which line many of the body’s surfaces, and endothelial cells, a single-layer type of epithelium, to create a two-channel system, the students hope to recreate the lung’s most important function: the exchange of carbon dioxide and oxygen.

“The idea is that it is possible to break it down into the simplest structure that can capture the most important processes,” said College team mentor Yitshak Zohar, professor of aerospace and mechanical engineering and director of the Integrated Microsystem Laboratory.

Historically, scientists have studied the way external stimuli affect cells using one of two methods. The first is on monolayers, using only epithelial or endothelial cells, which doesn’t allow scientist to capture the complex natures of cell signaling in a real organ. The second is to test treatments on animals — not only a complicated ethical issue, but also not the same as using human tissues. As Zohar said, there are basic biological differences that mean results of animal testing aren’t always transferable to humans. This chip could be the middle ground.

“Instead of performing tests in culture dishes or on mice, we can streamline the process through recreating an organ on a chip,” said student team leader Meagan Tran.

Future Applications

The actual lung on a chip, which will be on public display April 30 at the College of Engineering’s 2018 Design Day, is simple to make once scientists have the right cells. They layer the cells onto a clear silicone mold with a semipermeable membrane in between, and then expose the epithelial layer to gas flow and the endothelial layer to liquid flow. Zohar estimated that, once the engineers have a mold, each silicone “chip” would cost less than a dollar to produce.

Further down the line, the device could also have applications in personalized medicine, allowing a specific person’s cells to try out treatments in the system, so doctors and scientists can determine which treatment is best suited for that person.

“The drugs will be tailored to a particular person, not a particular disease,” Zohar said.

There is also the potential to coordinate with other researchers who are producing similar devices to simulate other organs, such as the gut, the breast or the prostate.

“Eventually, these devices can be hooked together to make a human system, and used to study metabolic absorption,” Tran said.