Ensuring the Accuracy of Tissue Testing

Project Title: Tissue-Replacement Control Slides

Team 17049 Members:

Paul Acosta, biomedical engineering

Alexander Day, biomedical engineering

Tatum Hale, biosystems engineering

Gabrielle Hutchens, biomedical engineering

Vy Nguyen, biomedical engineering

Sponsor: Ventana Medical Systems Inc.

Tech Could Save Lives, Time and Money

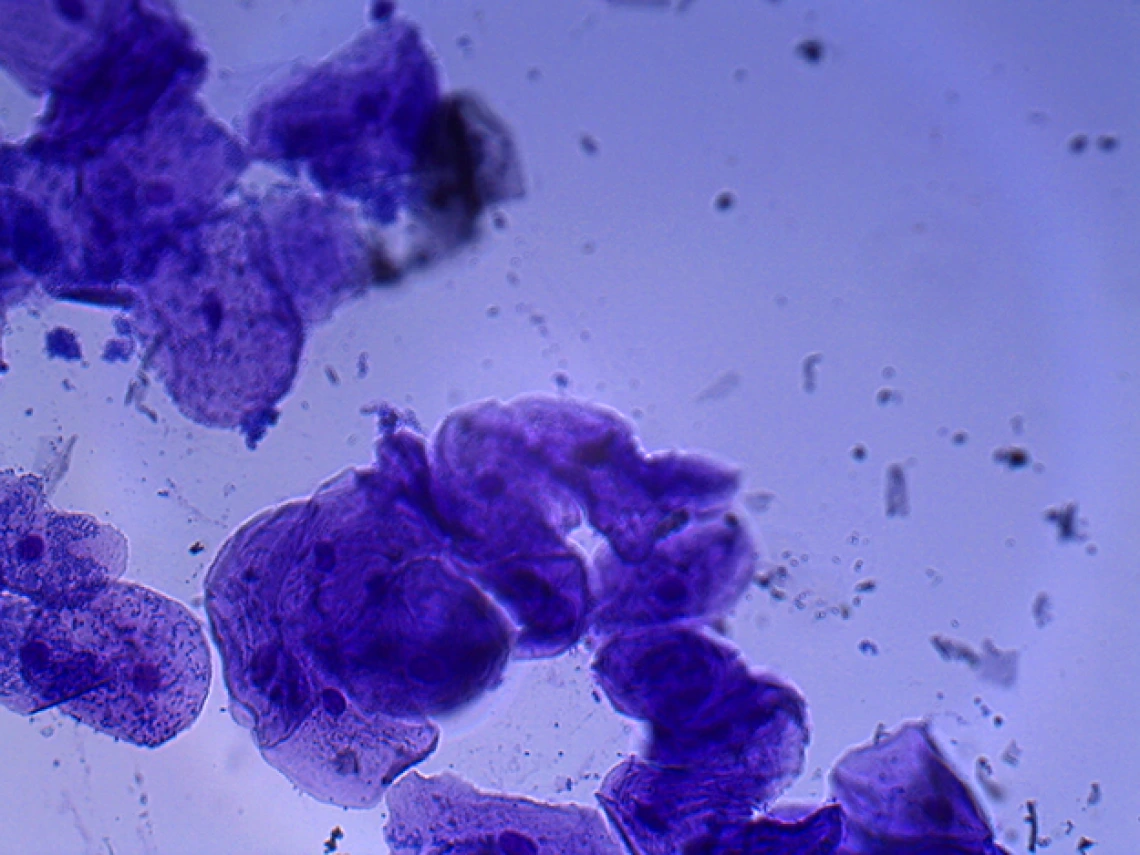

When scientists like those at Ventana Medical Center look at tissue under a microscope, every tissue sample looks a little bit different. That’s the point, after all: to look for microscopic differences in tissue that might be indicators of diseases such as cancer. They use colored stains that bind to different parts of the tissue: hematoxylin, a purple stain that binds to nucleic acids, and eosin, a pink stain that binds to substances such as amino acids and proteins.

Sometimes, however, minute differences are caused by the very machine that does the staining. Scientists have to account for whether differences between tissues are due to the tissues themselves or to the staining process. To do this, Ventana runs high sample sizes of tissue to reduce variability, which is neither cost nor time effective.

“If we had a control slide, we could greatly reduce the number of slides we need to run,” said Daniel O’Connor, Ventana’s mentor for the project. “That would save us quite a bit of time and money.”

A Student-Engineered Solution

Five students in the University of Arizona Engineering Design Program were tasked with creating a control slide, a nontissue slide that would stain in a simple, specific pattern the same way every time. If the scientists stain the control slide and it looks different from the specific pattern it should produce, then they know that variations in the stained tissue samples are likely due to the machine, not to inherent variations in the tissue.

“We want to know if our instruments here are functioning as designed,” O’Connor said.

Settling on a Stain

The team found two different materials that best suited their needs for a control slide.

“We needed something that has nucleic acid-like structures that would bind the stains,” said Gabrielle Hutchens, the student team leader.

After much trial and error — they tried Elmer’s glue, acetone, nail polish and even paper — the team settled on an art glue called methylcellulose, which binds well with hematoxylin, and nylon, which binds well with eosin.

“We have ideas, and they work,” Hutchens said. “It’s just implementing them and making them easy every time, and making something that’s going to be consistent for Ventana.”

Their project will be on public display at the College of Engineering’s 2018 Design Day on April 30.

“We’re always looking for more efficient and effective ways of doing things, and this just seems like a very big opportunity, mostly because it doesn’t only impact our department but all of the R&D in the organization, and even beyond that,” O’Connor said.