Measuring Cell Thickness With Electricity

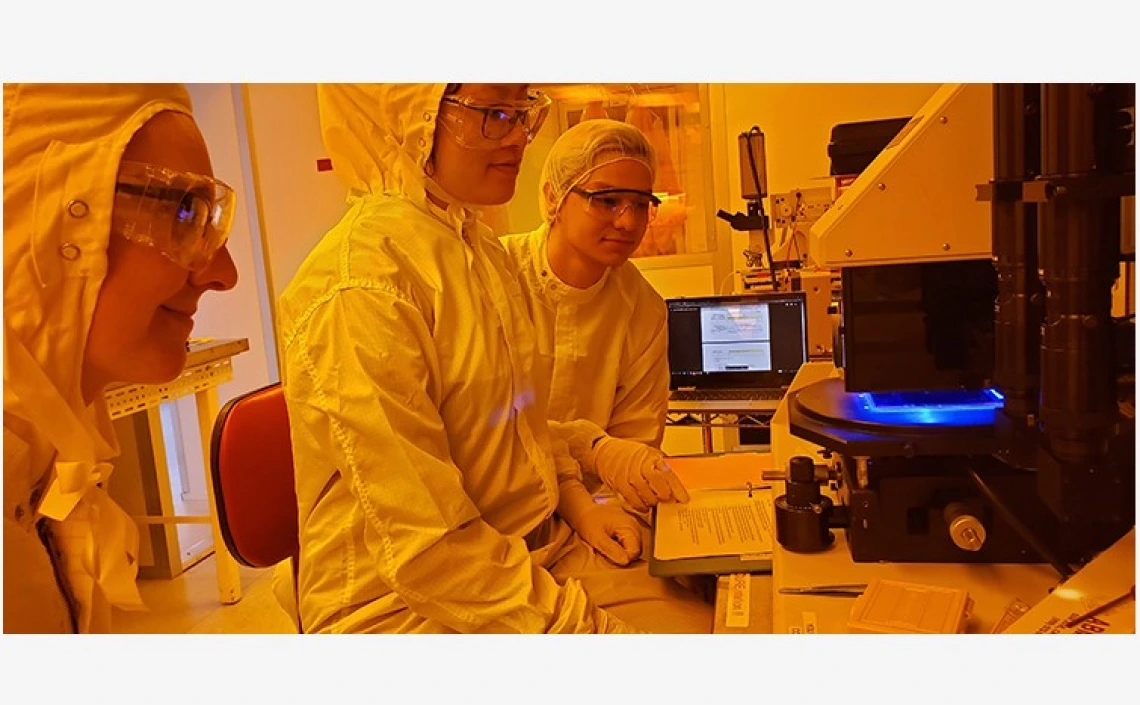

Courtney Comrie, Patarajarin Akarapipad, and Cody Thivener perform photolithography for their microfluidic chips

Project Title: Microfluidic System for Determination of Platelet Stiffness

Team 18071 Members:

Patarajarin Akarapipad, biomedical engineering

Courtney Comrie, biomedical engineering

Sean Copeland, biomedical engineering and mechanical engineering

Cody Thivener, biomedical engineering and electrical and computer engineering

Benjamin Weiss, biomedical engineering

Sponsor: UA Department of Biomedical Engineering

Portable, Accessible Point-of-Care Device

Many medications and implantable medical devices come with side effects. Some affect the mechanical properties of platelets in the blood, leaving people susceptible to clots when their cells are stressed. Because blood clots can lead to heart attack and stroke, medical researchers sometimes need to determine the stiffness of cells such as platelets to minimize these risks.

They do this through dielectrophoresis, a process that deforms cells by subjecting them to electricity. Scientists then use imaging technology to see how much the cells deformed at specific voltages and to determine their thickness.

“The stiffness of the cell is a determinant of whether the platelet becomes activated and then leads to blood clots,” said Dr. Marvin Slepian, associate head for clinical and industrial affairs in the UA Department of Biomedical Engineering and sponsor of five 2018-19 Engineering Design Program projects. “Wouldn’t it be great if we had a point-of-care device that could measure the change in individual cell stiffness right as the patient goes through the experience?”

Zapping Platelets for Diagnostics and Research

Team 18071 is creating a compact cell deformation system that can subject platelets to dielectrophoresis to cause deformation, image the deformation and ultimately determine the thickness of the cells.

“It has a lot of potential in diagnostics, but a lot of potential is also in research,” said team lead Courtney Comrie. “If you’re researching a new medical device or a new medication, you can see how it affects platelets.”

Current dielectrophoresis machines take up entire sections of laboratories, but the team is scaling the device down and making it portable. At just over a foot tall and just under a foot wide, it’s designed to fit easily on a lab bench. The device will also display data on a regular smartphone screen.

“We’ll have an attachment that will hold the phone in place so it can look through the microscope at the right angle,” Comrie said. “We want to use the smartphone camera directly. It’s very accessible – everyone has one.”

Taking Their Research on the Road

Slepian suggested the team gain experience submitting and presenting their research. So, not only did they submit a summary and present at the UA College of Medicine’s 2019 Data Blitz in February, but they’re also in the process of applying to the ASAIO’s 65th annual conference as part of the organization’s young innovators initiative. With their initial proposal accepted, they’re working on a final report for the conference’s 7th annual student design competition.

“It’s been positive seeing our effort actually work and reaping the benefits,” Comrie said. “I think it’s been a good experience to put in these applications to these conferences. It’s validating the work we’re doing.”

Learn more about the project, and the team’s progress, at Engineering Design Day 2019 on April 29.