Teams Take On Coronavirus Challenges

Unable to gather in groups or use on-campus resources for their projects, students and sponsoring companies are finding creative ways to complete senior design projects.

Units across campus have shifted from in-person interactions to virtual meetings, and Interdisciplinary Capstone is no exception. But, since engineering design projects are centered around construction, collaboration and other hands-on work, many teams have had to apply their engineering know-how and problem-solving skills to adapt their projects to new circumstances.

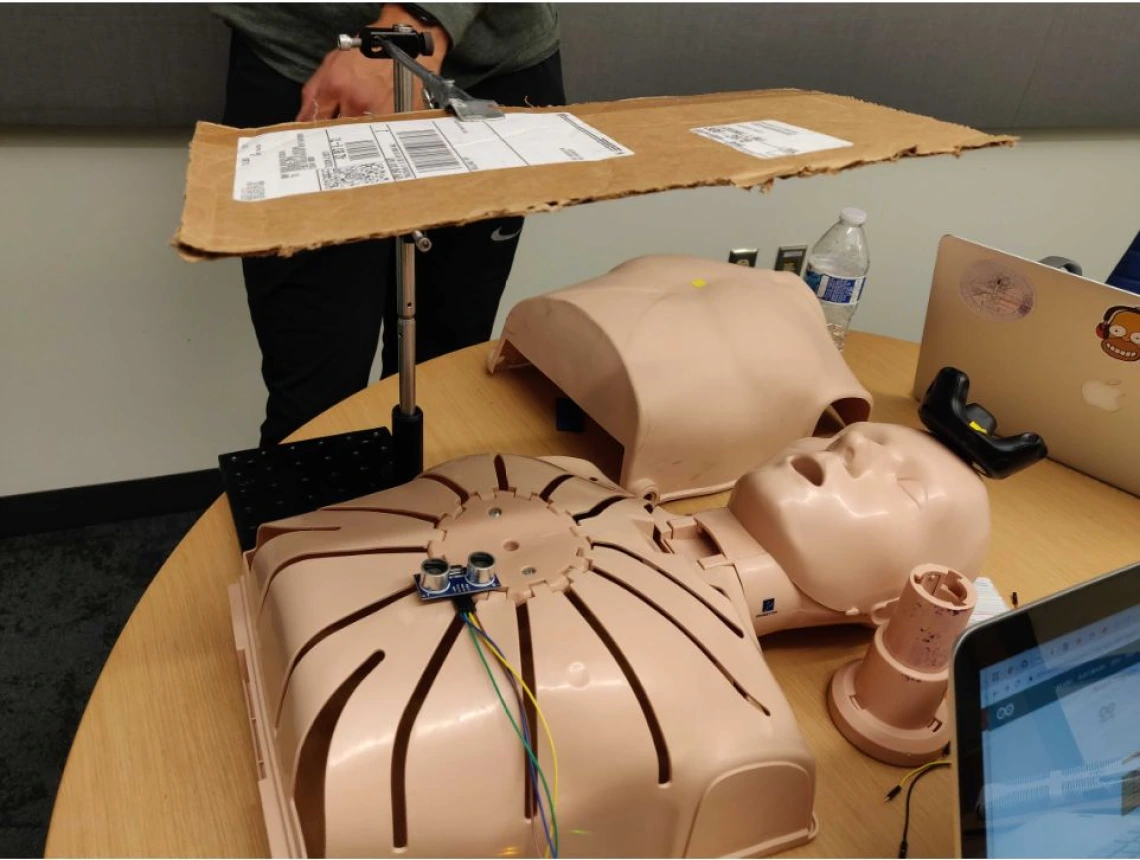

Ultrasonic CPR

Team 19088, sponsored by the Arizona Center for Accelerated Biomedical Innovation, is developing a mixed-reality system that provides real-time feedback to people practicing CPR. The deliverable consists of a virtual reality headset and an elastic glove equipped with sensors that can monitor a user’s movements on a dummy.

“I was interested in applying new technologies, like augmented reality, to potentially life-saving and real-world scenarios,” said electrical and computer engineering team member Minh Nguyen.

One of the team’s biggest challenges was finding a method sensitive enough to determine the correct distance the chest should be pushed down in a CPR chest compression. When the accelerometer they tried at first proved to be an ineffective method for measuring depth, they did some out-of-the-box thinking and chose ultrasonic sensors instead.

“They’re used in many automated factories, process plants, robots and even cars,” said team lead Nadine Najdawi, an electrical and computer engineering student. “With some research, we found that the ultrasonic sensor can provide the distance between objects with little error.”

Before the outbreak, the team met two to three times a week at the Bioscience Research Labs, but then they began having meetings less frequently, and with no more than four people. Now, they’ve shifted to meeting only virtually.

“Due to the stay-at-home order, we are unable to 3D-print some of our parts,” Najdawi said. “However, these are mainly design and aesthetic issues. The functionality of our project remains intact.”

Epileptic Seizure Detection

Team 19063 is creating an epileptic seizure detection device for sponsor Intel. Team lead and biomedical engineering student Alejandro Ortega said the opportunity to build a device that could meaningfully impact people’s lives made this project his number one choice.

Their original task was to build an open source system that could detect when a seizure is occurring and notify a person’s caregiver. The team planned a series of clinical trials in Colombia to collect data with their optical sensors and train an artificial intelligence model to recognize seizures, but they had to cancel the trials due to the outbreak.

They’ve shifted gears to focus on creating an easy-to-use data collection system that will train an artificial intelligence model. Any caregiver can operate the system to gather and tag seizure information, helping teach the model how to recognize a seizure. By sharing their results and documentation with the open source community, the team hopes the system can eventually be expanded into a device that warns caregivers when a seizure is occurring.

“This way, our analysis and efforts are not wasted. The original intent of helping people is preserved and will hopefully grow in the open source community with proper documentation,” Ortega explained. “I’ve gained skills that will help me thrive in my career, because I was not afraid of taking on a task that was outside of my discipline. And that challenged me to learn and create something absolutely new.”

3D-Printing Drones… at Home

Team 19079 is developing a system to create low-cost, 3D-printable and easily assembled remote-operated vehicles for Raytheon Missile Systems. This will provide operators a way to create several types of vehicles without needing an expensive supply chain.

But when campus labs and vendors throughout Tucson shut down, the team was left without access to a 3D printer on which they could create the parts for their project. They decided to buy a build-it-yourself printer so they could produce the parts themselves, but a problem with the machine left them stumped.

Their mentors said if worse came to worst, the company could print the team’s parts for them. But they offered something even more helpful first: a Raytheon engineer who walked the students through how to fix the problem. Now, the team is on track to deliver a tangible product.

The project’s sponsors, Jim Bakarich and Rene Van Alstine, are both alumni of the College of Engineering – Bakarich in mechanical engineering and Val Alstine in electrical and computer engineering.

“The students are doing well, applying solid product development strategies and tackling the problems as a team,” said Bakarich, an engineering fellow at Raytheon and product development lead at the Raytheon Bike Shop. “We appreciate the opportunity to help shape these student engineers, who are critical to the future of our industry.”