Longtime Neighbor, First-Time Sponsor

This year, Interdisciplinary Capstone is welcoming new sponsor RMC Boeckeler, a local manufacturer of sample preparation equipment for nanoscale research.

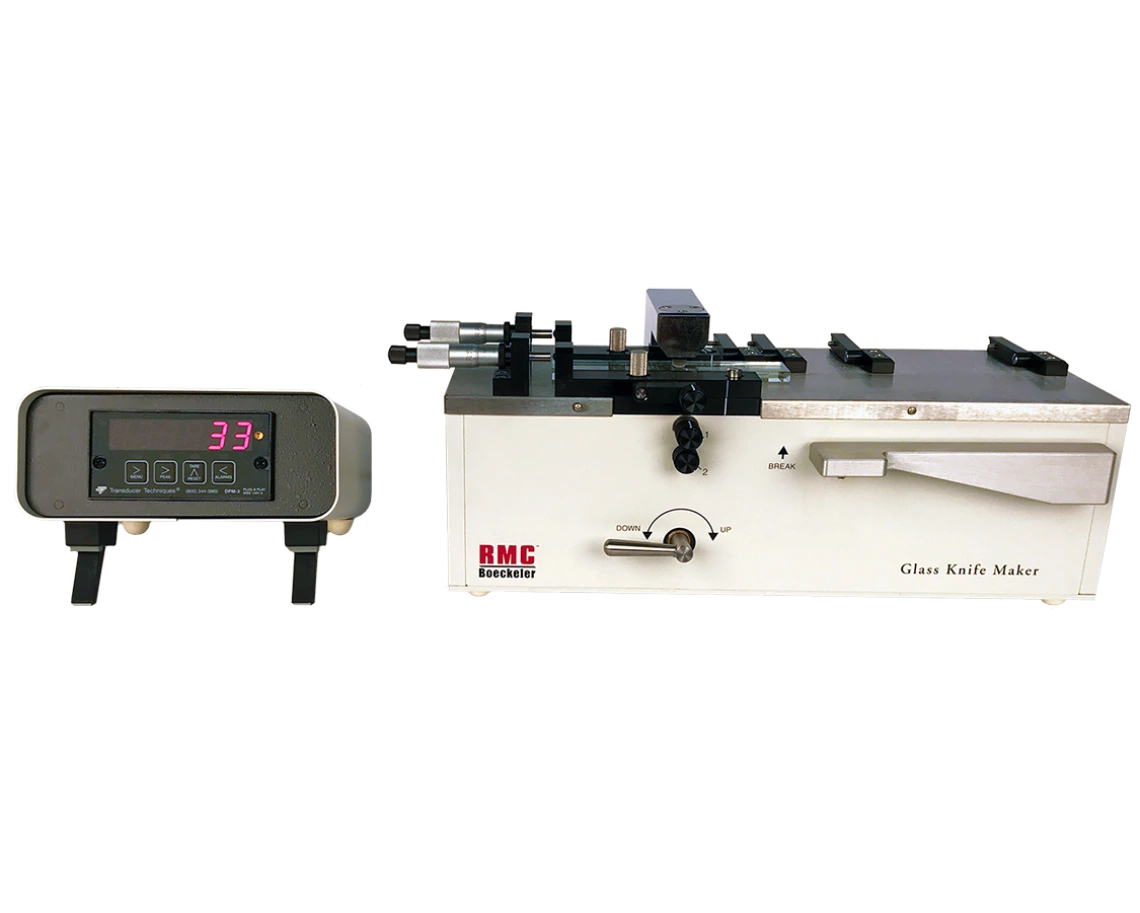

RMC Boeckeler is enlisting Wildcat Engineers to improve the design of the company's glass knife maker.

RMC Boeckeler has been located in Tucson since it began in 1942 as Boeckeler Instruments Company. When current CEO Peter Strucks acquired the company in 2019, he made it a point to work more closely with the University of Arizona.

Originally from Holland, Strucks has a background in management consulting. When he came to the United States, he worked with hedge funds in New York, looking for potential acquisitions in the analytical instrument industry. When he came across RMC Boeckeler, it didn’t fit the acquiring company’s size requirements. So he decided to acquire it himself.

“The rest is history,” he said.

RMC Boeckeler makes ultramicrotomes, an instrument which is used to slice tissue samples or other material in very thin slices — about 30 mm — so they can be analyzed by electron microscopes. It’s one of only two companies in the world that manufacture the devices. Both RMC Boeckeler and its competitor, Leica, also sell glass knife maker machines, which produce ultra-thin blades for the ultramicrotomes. These offer a much cheaper alternative to diamond knives, at a cost of only a few dollars compared with $5,000-6,000.

While touring the University of Sydney in 2019, Strucks asked a professor if the university had one of Boeckeler’s glass knife makers.

“I have one, but our students prefer the one from Leica,” he said. “Yours is better, but theirs is more user friendly.”

That confirmed the observations Strucks had made so far, that while Boeckeler’s GKMT2 Glass Knife Maker had excellent precision and other capabilities, the look and feel could use some improvement.

“Some of our projects, though they are quite mechanically sound, look old and tired. But they still sell,” he said. “So we imagine, ‘What if we make it look better?’ We can do a lot more. I’ve got to bring sexy back.”

Around the same time, he attended a meeting for the Arizona Tech Council and came across a booth for the UA Department of Aerospace and Mechanical Engineering.

“I was thinking, ‘I know I need to get involved with the university,’” he said. “I’ve got a company here which makes a unique product. We’re one of two companies in the world that makes this. And the university has interesting, skilled people, young people, with smart ideas who are right here on the forefront with the latest technology and who have gotten a good education.”

He decided to sponsor two projects through the Interdisciplinary Capstone Program: one for students to develop a more user-friendly version of the glass knife maker, and another to develop a motorized stage similar to what Leica, already offers.

In the meantime, he hired his first intern, Leonardo Rivera, who just finished his initial year in the college and is deciding between a major in chemical and mechanical engineering. Strucks said Rivera has been an asset to the RMC Boeckeler team so far.

“Once these students graduate, they’re potential candidates for me to hire,” Strucks said. “I want to try to get first pick. While we may be a small company, we are growing, and we offer something the larger engineering companies don’t offer: the chance to see a product through from initial stages of development to market launch.”