Engineering Undergraduates Contribute to OSIRIS-REx Mission

Shawn Cherian, Zane Craddock, Michael Gibson, Aaron McCommon, Andrea Ochoa and Jinhua Oyuang are building a device to test the thermal conductivity of samples from Bennu, a near-Earth asteroid.

Project Title: Apparatus for measuring the thermal conductivity of returned samples from asteroid Bennu

Team 21005 Members:

Shawn Cherian, mechanical engineering

Zane Craddock, systems engineering

Michael Gibson, materials science and engineering

Aaron McCommon, systems and industrial engineering

Andrea Ochoa, electrical and computer engineering

Jinhua Oyuang, mechanical engineering

Sponsor: University of Arizona Lunar and Planetary Laboratory

The University of Arizona is leading NASA’s OSIRIS-REx mission, the first U.S. mission to return samples from an asteroid to Earth. By collecting and analyzing a sample from the surface of a near-Earth asteroid called Bennu, scientists seek to answer questions about the makeup of the solar system and the origins of life as we know it. Currently, the OSIRIS-REx spacecraft is still in Bennu’s vicinity, with plans to begin its two-year journey back to Earth in May 2021.

For their Interdisciplinary Capstone project, students on team 21005 are contributing to a future phase of the mission by developing a method to test the thermal conductivity of asteroid samples.

“I wanted to do this project because I’m really interested in astronomy, said mechanical engineering student Jinhua Ouyang. “As a Wildcat, I’m very proud of OSIRIS-REx.”

Typically, measuring the thermal conductivity of a material means cutting it into a flat shape so that two flat surfaces, similar to hot plates, can be mounted to the sample.

“Because the Bennu materials are so precious and rare, we can’t modify them, we can’t touch them – we can’t even expose them to the environment,” said Zane Craddock, a systems engineering major and team lead. “Sample protection is our No. 1 priority. So, without theoretically touching the sample, we have to measure its thermal conductivity, which hasn’t really been done before except in really limited ways.”

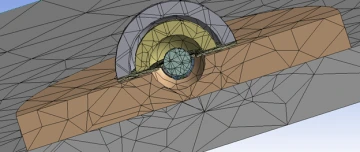

The team's current design for their device has space for a vacuum chamber, which will hold the sample, in the center.

This means the samples will need to remain in a vacuum chamber while they’re being tested. Instead of the traditional method, the team is devising a way to use radiation, so that heat is transferred through induction rather than direct contact.

The team has gone through several versions of a design for a device and plans to begin fabrication in February. They will be testing its accuracy using material from a meteorite, with a makeup similar to what the OSIRIX-REx team expects from the Bennu sample.

The team said their biggest challenge so far has been learning to work in a system that’s designed for a vacuum chamber – something none of them have done before. They’ve also tried to create a design that can accommodate different-sized samples. COVID-19 restrictions have made it difficult to work together in person as well. However, having students with different engineering background has been invaluable, they agreed.

“Seeing the different disciplines in action has been extremely helpful in this,” said materials science and engineering major Michael Gibson. "I have a materials science background, so my focus is on what we’re going to make the apparatus out of. But having mechanical engineers that know a lot about heat transfer and can analyze it properly; systems engineers that actually organize everything; and an electrical engineer that actually knows how to run experiments, use LabVIEW and connect wires is also going to be insanely useful.”