Mitigating Distortions in 3D-Printed Parts

Team 18014 is working on mitigating distortions in 3D-printed parts with Honeywell. Front row, left to right: J.C. Martinez and Morgan Swanson. Back row, left to right: Zach Minnick, Lucas Stolburg and Zach Ondrejka.

Project Title: Additive Manufacturing Process and Dimensional Control

Team 18014 Members:

Juan Carlos Martinez, mechanical engineering

Zachary Minnick, industrial engineering

Zachary Ondrejka, mechanical engineering

Lucas Stolberg, materials science and engineering

Morgan Victoria Swanson, materials science and engineering

Kathleen Van Atta, material sciences and engineering

Sponsor: Honeywell Aerospace

Honeywell Aerospace is one of the most loyal partners of the UA Engineering Design Program, having supported more than 70 projects in the last 11 years, including 12 in the 2018-2019 academic year alone – the most projects a single company has sponsored throughout the life of the program and in a single year.

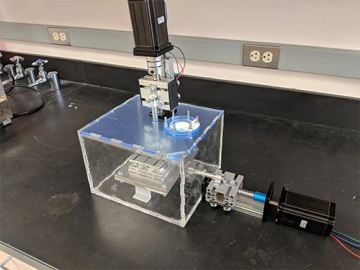

For one of those projects, Team 18014 is making a turbine blade using additive manufacturing, or 3D printing, using metallic materials on a Honeywell-owned advanced 3D printer. Creating parts layer by layer allows engineers to produce complex designs quickly and at low cost compared to traditional manufacturing methods. With modern 3D printers, many printed parts are usable directly for their intended function even in demanding conditions.

“Within the additive manufacturing industry, especially with metal printing for aerospace applications, the geometry of parts can be quite complex,” said mechanical engineering major Zach Ondrejka. “This offers a lot of benefits, but one of the big drawbacks is controlling distortions when printing parts.”

Down With Distortions!

The team’s project is centered on accounting for these distortions, caused by heating, melting, solidification and cooling during additive manufacturing. Their goal is to make sure their final product comes within 0.005 inches of the dimensions and geometry of their design parameters.

“When you print it, it’s not going to conform to the exact geometry of the design,” said Suresh Sundarraj, one of Team 18014’s corporate sponsors. “The team’s job is to figure out what we need to do on the simulation side to compensate for these distortions. How closely can they achieve the design as in the original CAD file?”

The team started by running simulations of how the blade would turn out if printed at different orientations – does turning the design on its side so that a different feature prints first reduce distortion? Though they knew from their research to expect deviations, they were surprised by just how much the printed part deformed after cooling – up to 0.036 inches at some points.

Sundarraj advised the team at a meeting: It’s more important to achieve the end goal than the plan. Have a flexible plan, make sure everyone knows how to use the software on their own and watch the simulations as they’re running to see where distortions start to occur.

The team members chose the project because 3D printing is one of today’s fastest-developing and most promising manufacturing methods. Ondrejka learned in one of his classes about how 3D printing could improve the efficiency of engines in the aerospace industry by allowing the manufacture of turbine blades with built-in cooling networks, for example.

“Additive manufacturing is pretty much the next step for manufacturing, because it gives you so much customizability,” said team lead and industrial engineering major Zachary Minnick. “Metal 3D printing is fairly rare to see, so I was really interested to dive into that.”

A Staunch Supporter

Honeywell’s partnership with the University of Arizona continues to grow: The company is also donating a 3D printer to the College of Engineering this summer for future use by students and the Engineering Design Program. Come and see the results of Team 18014’s experimentation – and the other 11 Honeywell teams – at Engineering Design Day 2019 on April 29.